Process flow:

One-click cleaning start - pump pressurization start - cleaning three levels of filtration - spray rinse screen, film removal liquid circulation, cleaning can be set times of time - spray rinse - rinse water filter bag discharge -- Blow air to dry the screen.

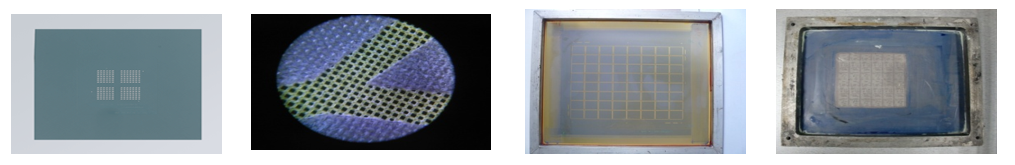

Field of Application:

The PGT-1200T electric development cleaning machine is suitable for steel mesh, copper mesh, micro mesh and crystal disk and other types of mesh cleaning;It is also suitable for cleaning circuit board, fixture, scraper and other similar products and appliances.

Equipment features:

? Dedicated to cleaning printing ink, glue, paste, etc.;

? Large cleaning surface, suitable for 47 "*47 screen placement;

? The cleaning pressure can be adjusted independently, suitable for any material screen;

? Unique S-shaped exhaust design for lower liquid consumption;

? The equipment adopts precision three-stage 0.45um filtration system, solvent recycling;

? Humanized design: one-click operation and automatic filling and draining function, the operation is very simple;

? System integration of global quality components: to ensure good quality, stable performance, long service life;

? Cleaning and rinsing process ensures cleanliness, liquid pressure can be displayed through the pressure gauge on the panel;

? Equipped with a despotic professional air gun, adding humanized design manual drying and other functions (equipment highlights);

? Equipped with 2 80L solution cleaning tanks, solution cleaning tank with filter ink removable filter screen, easy to maintain (equipment highlight);

? All stainless steel body: beautiful, wear resistance, corrosion resistance, acid, alkaline cleaning fluid. Meet environmental requirements and standards.

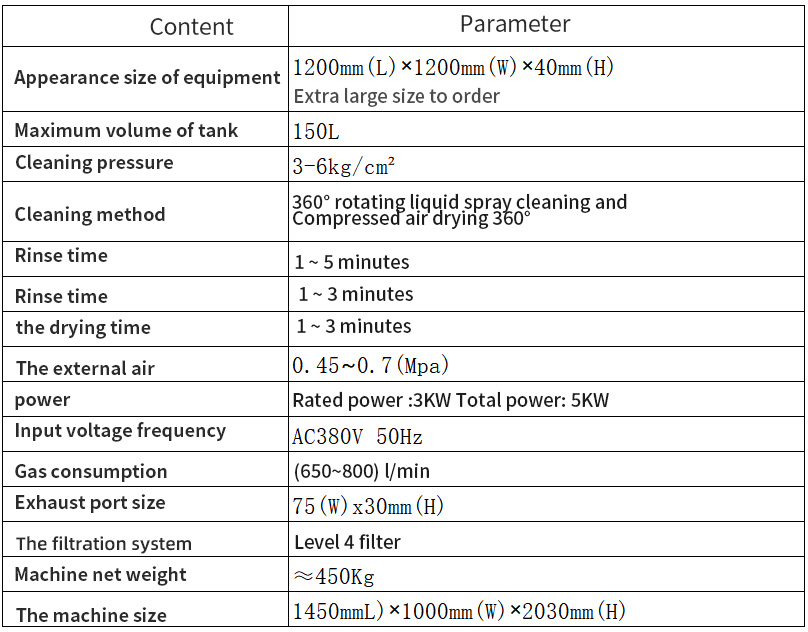

Technical parameters: